Note

Click here to download the full example code

Failure analysis for short fiber composites#

This example shows how to evaluate failures of a short fiber reinforced part.

As part of the short fiber workflows, you can evaluate and plot Tsai-Hill

type orientation tensor-dependent failure criteria. This example shows

how to configure the DPF operator short_fiber_failure_criterion_evaluator

to compute such failure criteria.

The model shown in this example consists of a tensile specimen made of a short glass fiber reinforced thermoplastic injection molded from both sides.

Note

The evaluation of failure criteria in short fiber workflows is a beta feature, introduced in Ansys 2021 R2.

Set up analysis#

Setting up the analysis consists of loading Ansys libraries, connecting to the DPF server, and retrieving the example files.

Load Ansys libraries.

import ansys.dpf.core as dpf

from ansys.dpf.composites.constants import FailureOutput

from ansys.dpf.composites.example_helper import get_short_fiber_example_files

from ansys.dpf.composites.server_helpers import connect_to_or_start_server

Start a DPF server and copy the example files into the current working directory. These files are needed:

Mechanical APDL result (RST) file containing the simulation results

Engineering Data (MATML) file containing the material properties of the composite

Mechanical APDL input file (DS.DAT) containing the fiber orientation tensor data

server = connect_to_or_start_server()

composite_files_on_server = get_short_fiber_example_files(server, "short_fiber")

Set up data sources#

Set up the data sources.

data_sources = dpf.DataSources()

data_sources.add_file_path(composite_files_on_server.engineering_data, "EngineeringData")

data_sources.add_file_path(composite_files_on_server.dsdat, "dat")

data_sources.set_result_file_path(composite_files_on_server.rst)

Initialize DPF model#

Initialize the DPF model.

model = dpf.Model(data_sources=data_sources)

mesh = model.metadata.meshed_region

Plot results#

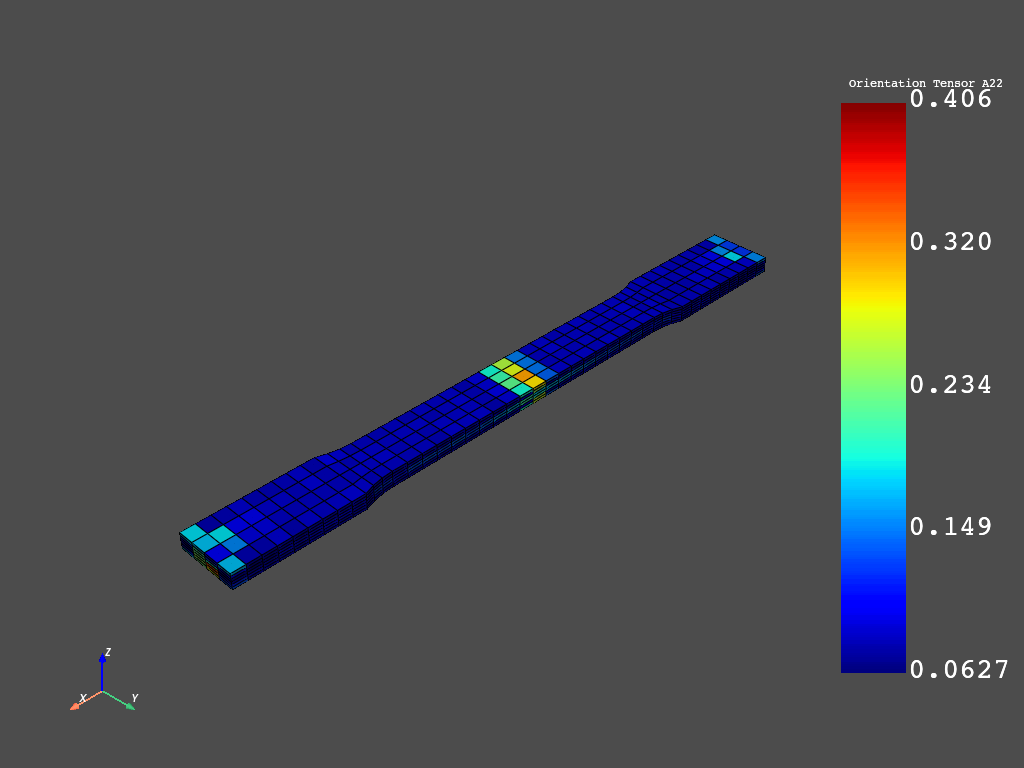

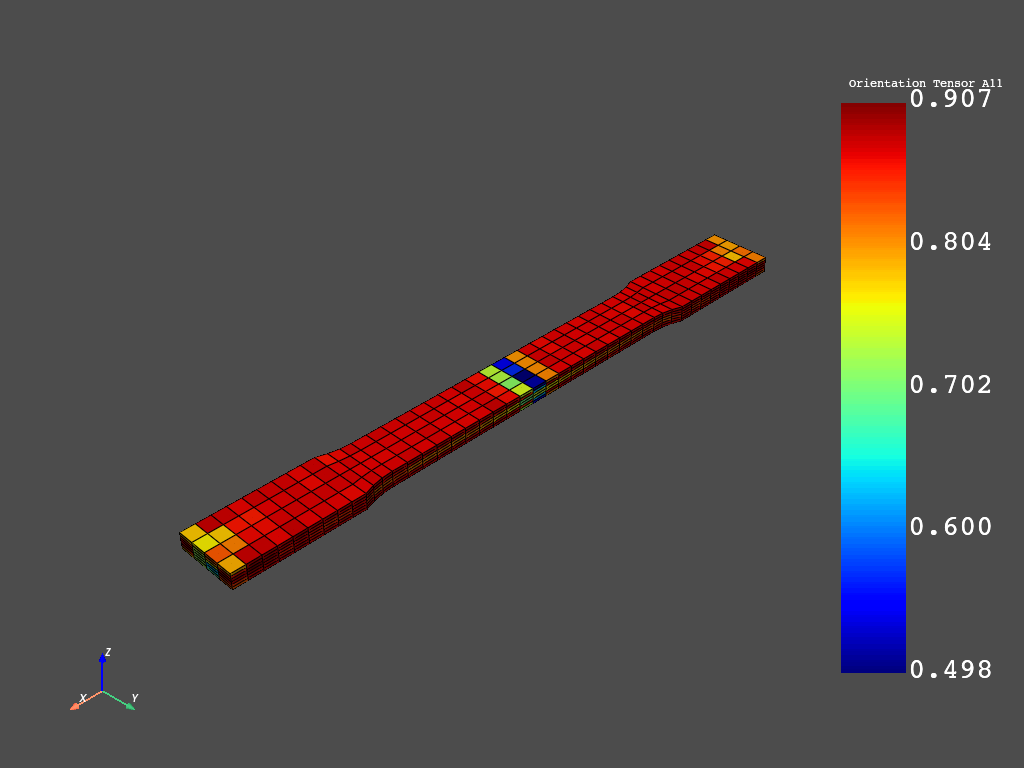

Plot the two largest eigenvalues (a11 and a22) of the fiber orientation tensor. Note that the plots reveal the presence of a weld line in the middle of the specimen.

field_variable_provider = dpf.Operator("composite::inistate_field_variables_provider")

field_variable_provider.inputs.data_sources(data_sources)

field_variable_provider.inputs.mesh(model.metadata.mesh_provider)

field_variables = field_variable_provider.outputs.fields_container.get_data()

a11 = field_variables[0]

a11.plot()

a22 = field_variables[1]

a22.plot()

Configure and evaluate#

Configure the short fiber failure criterion evaluator and evaluate. Note that you can specify optional time and mesh scoping inputs.

sf_op = dpf.Operator("composite::short_fiber_failure_criterion_evaluator")

sf_op.inputs.streams_container(model.metadata.streams_provider)

sf_op.inputs.data_sources(data_sources)

sf_op.inputs.stress_limit_type("ultimate") # "yield" or "ultimate" (default)

sf_op.run()

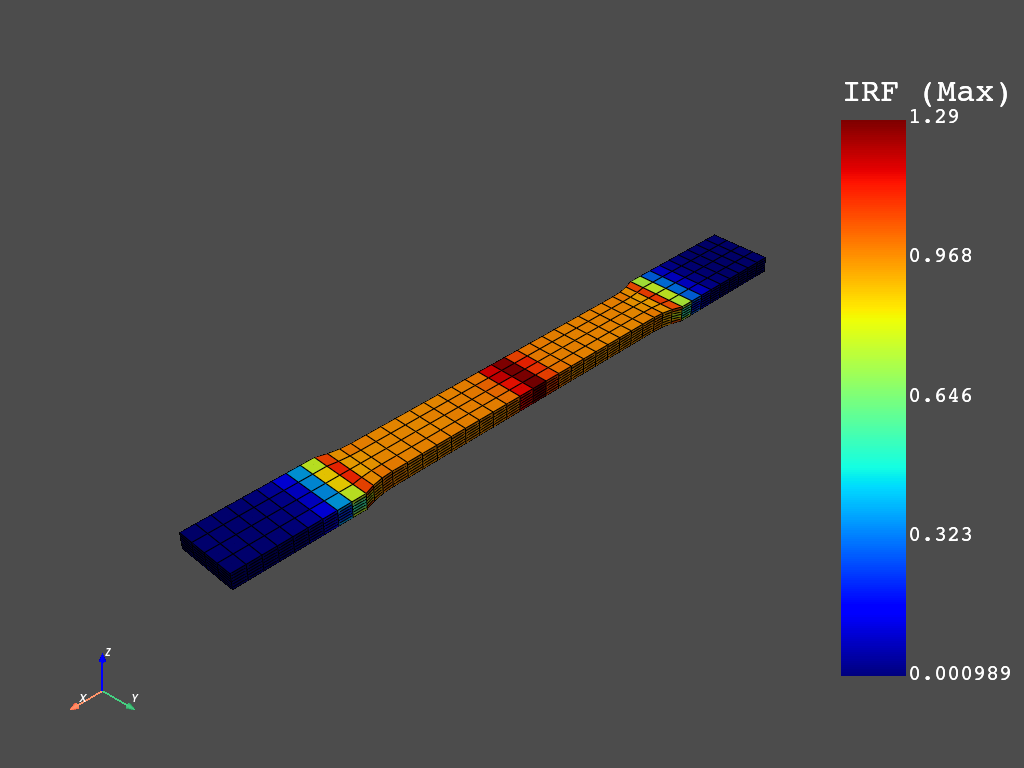

Compute and plot results#

Compute and plot the maximum failure value per element.

mat_support_operator = dpf.Operator("mat_support_provider")

mat_support_operator.connect(4, data_sources)

minmax_per_element = dpf.Operator("composite::minmax_per_element_operator")

minmax_per_element.inputs.fields_container(sf_op)

minmax_per_element.inputs.mesh(mesh)

minmax_per_element.inputs.material_support(mat_support_operator)

max_failure = minmax_per_element.outputs.field_max.get_data()

max_failure_value = max_failure.get_field({"failure_label": FailureOutput.FAILURE_VALUE})

mesh.plot(max_failure_value, show_edges=True)

Total running time of the script: ( 0 minutes 4.165 seconds)