Note

Go to the end to download the full example code.

Thermal analysis#

This example shows how to evaluate a thermal analysis. The simulation’s thermal analysis results are also the input of a structural analysis. Therefore, the RST file contains temperature and structural results.

The example imitates a printed circuit board (PCB) that was modeled with Ansys Composites PrepPost (ACP), using the solid model feature to generate the volume mesh.

Descriptions of how to extract temperatures for a specific ply and material are provided.

Note

When using a Workbench project,

use the get_composite_files_from_workbench_result_folder()

method to obtain the input files.

Set up analysis#

Setting up the analysis consists of loading the required modules, connecting to the DPF server, and retrieving the example files.

import ansys.dpf.core as dpf

import numpy as np

from ansys.dpf.composites.composite_model import CompositeModel

from ansys.dpf.composites.example_helper import get_continuous_fiber_example_files

from ansys.dpf.composites.layup_info import get_all_analysis_ply_names

from ansys.dpf.composites.ply_wise_data import SpotReductionStrategy, get_ply_wise_data

from ansys.dpf.composites.select_indices import get_selected_indices_by_dpf_material_ids

from ansys.dpf.composites.server_helpers import connect_to_or_start_server

server = connect_to_or_start_server()

composite_files = get_continuous_fiber_example_files(server, "thermal_solid")

Initialize the model#

Initialize the composite model with the composite files and server. The model provides access to the mesh, results, lay-up, and materials.

composite_model = CompositeModel(composite_files, server)

Get temperature results#

The temperatures are stored under structural_temperature.

temp_op = composite_model.core_model.results.structural_temperature()

temperatures_fc = temp_op.outputs.fields_container()

Get ply results#

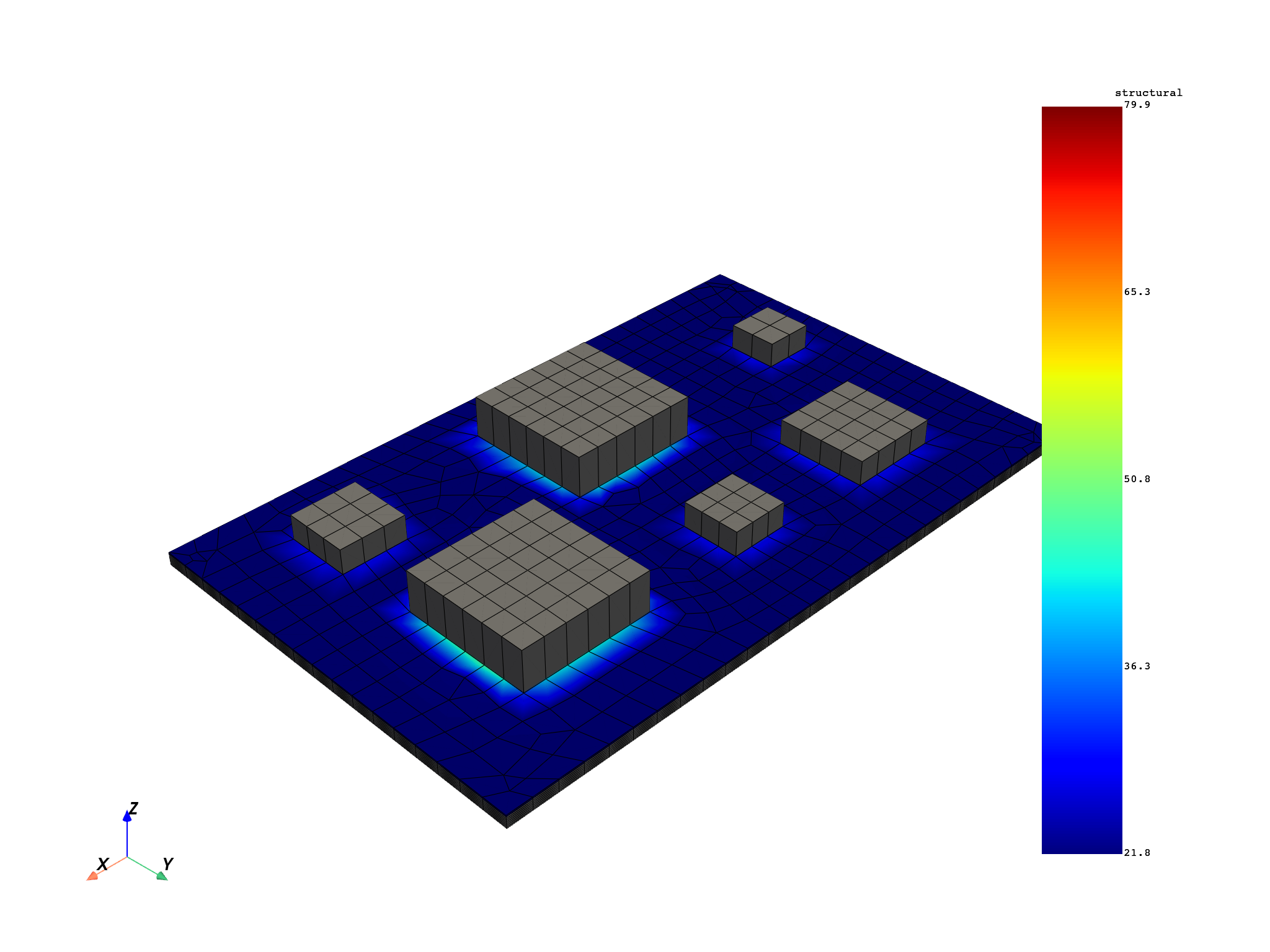

Extract the ply-wise results by passing the ply name

to the function get_ply_wise_data().

all_ply_names = get_all_analysis_ply_names(composite_model.get_mesh())

print(all_ply_names)

# The component of the temperature is 0 which is the default value.

nodal_values = get_ply_wise_data(

field=temperatures_fc,

ply_name="P1L1__ModelingPly.8",

mesh=composite_model.get_mesh(),

spot_reduction_strategy=SpotReductionStrategy.MAX,

requested_location=dpf.locations.nodal,

)

composite_model.get_mesh().plot(nodal_values)

['P1L1__p1_2_4_6', 'P1L1__p5', 'P1L1__p3', 'P1L1__ModelingPly.8', 'P1L1__ModelingPly.4', 'P1L1__ModelingPly.3', 'P1L1__ModelingPly.1', 'P1L1__ModelingPly.2', 'P1L1__ModelingPly.5', 'P1L1__ModelingPly.6', 'P1L1__ModelingPly.7']

(None, <pyvista.plotting.plotter.Plotter object at 0x7f59acdc7ed0>)

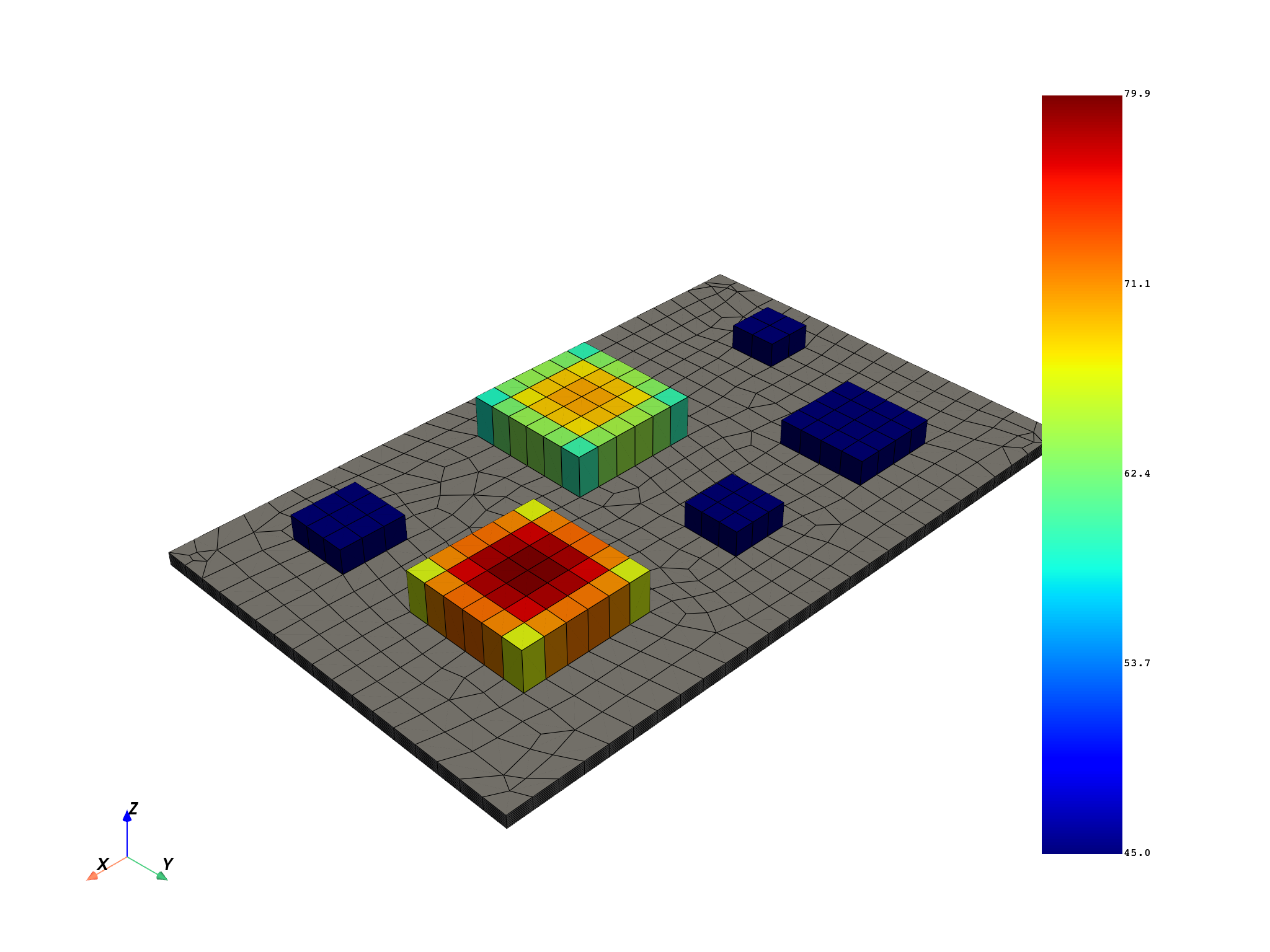

Get results by material#

You can filter the results by material. In this example, the element-wise maximum temperature is extracted for the material Honeycomb Aluminum Alloy.

print(composite_model.material_names)

material_id = composite_model.material_names["Honeycomb Aluminum Alloy"]

# get the last result field

temperatures_field = temperatures_fc[-1]

material_result_field = dpf.field.Field(location=dpf.locations.elemental, nature=dpf.natures.scalar)

# performance optimization: use a local field instead of a field which is pushed to the server

with material_result_field.as_local_field() as local_result_field:

element_ids = temperatures_field.scoping.ids

for element_id in element_ids:

element_info = composite_model.get_element_info(element_id)

assert element_info is not None

if material_id in element_info.dpf_material_ids:

temp_data = temperatures_field.get_entity_data_by_id(element_id)

selected_indices = get_selected_indices_by_dpf_material_ids(element_info, [material_id])

value = np.max(temp_data[selected_indices])

local_result_field.append([value], element_id)

composite_model.get_mesh().plot(material_result_field)

{'Honeycomb Aluminum Alloy': np.int32(1), 'UD Resin Epoxy/E-Glass': np.int32(2)}

(None, <pyvista.plotting.plotter.Plotter object at 0x7f599c25e710>)

Total running time of the script: (0 minutes 8.013 seconds)